Understanding PVC and XLPE Cables

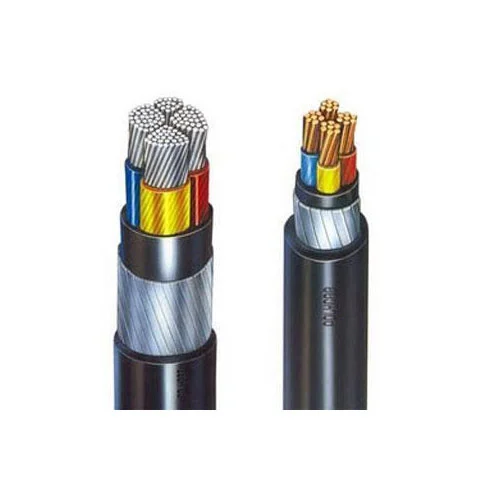

When it comes to power cables, two of the most commonly used types are PVC (Polyvinyl Chloride) and XLPE (Cross-Linked Polyethylene) cables. Each of them serves a distinct purpose in the electrical industry based on their unique properties for different applications. Understanding the differences between PVC and XLPE electrical cables is essential to select the right cable type for a specific application. Let’s take a closer look at the characteristics, applications of PVC and XLPE cables, and performance of these power cables.

Mahendra Fact File: PVC cables operate well at lower temperature but can be limited in high temperature environments (up to 70℃ for continuous use). XLPE cables can withstand higher temperatures (up to 90℃ for continuous operation), making them suitable for harsh environments.

What is a PVC Cable?

PVC (Polyvinyl Chloride) cables are a widely used type of electrical cable known for their flexibility, waterproofing, and affordability. These cables are usually used in low-voltage and indoor applications such as household wiring, appliance wiring, and low-voltage power systems due to their flexibility and affordability.

Properties of PVC Cables

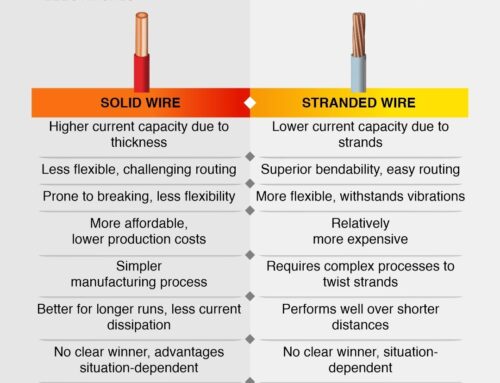

Flexibility: PVC cables are known for being flexible and easy to handle, making them ideal for household and general-purpose wiring.

Waterproofing: PVC offers effective waterproofing, which adds to its reliability for indoor wiring.

Affordability: Compared to other cable types, PVC cables are cost-effective, which makes them a popular choice for many small-scale operations.

What is an XLPE Cable?

XLPE (Cross-Linked Polyethylene) cables take insulation to a higher level by using polyethylene that has undergone a cross-linking process. This process enhances the cable’s resistance to high temperature and chemical exposure, making XLPE cables suitable for more demanding environments, such as underground and overhead transmission lines, and industrial power systems.

PVC vs. XLPE – Which one is better?

Choosing between PVC and XLPE cables depends on the type of electrical load, installation environment, and required durability.

Electric Load: PVC is best for low-voltage applications like household wiring and small appliances. XLPE, however, is ideal for high-voltage situations, such as industrial power distribution or larger electrical grids.

Installation: PVC cables are easier to install, while XLPE cables are more suited for harsh environments like underground or overhead, where resistance to heat and chemicals is essential. This makes installation more cumbersome.

Chemical Resistance: PVC provides basic chemical resistance, suitable for indoor applications with minimal exposure. XLPE offers superior chemical resistance, making it appropriate for environments where chemical exposure is a concern.

Durability: PVC cables are typically used where lower wear and tear is expected. XLPE, on the other hand, is more durable and ideal for environments requiring robust cables.

Cost Comparison of PVC vs XLPE Cables: PVC cables are initially cheaper, while XLPE cables provide better long-term value due to their durability and resistance. Although XLPE is costlier, its superior performance can lower maintenance costs over time.

Performance Rate: PVC works well in low-voltage, indoor environments, while XLPE can handle higher temperatures, large voltage loads, and chemical exposure, making it suitable for outdoor environments.

Use Cases: PVC is best suited for residential wiring, low-voltage applications, and situations where flexibility and cost are important. XLPE is a go-to choice for industrial use, especially in high-voltage transmission, and areas exposed to high heat or chemicals.

Conclusion

PVC and XLPE cables serve distinct purposes. PVC is affordable and flexible, suitable for low-voltage and indoor applications. In contrast, XLPE provides superior durability, higher temperature tolerance, and better chemical resistance, ideal for industrial and transmission uses.

When choosing the right cable type: PVC vs XLPE, consider the operating environments, electrical load, and use case. For demanding applications, XLPE is preferable; for cost sensitive, low-voltage needs, PVC is more practical. At Mahendra Electricals, high-quality PVC and XLPE cables are available, for your specific needs, whether for home wiring or large industrial systems.

FAQs

- What are the main differences between PVC and XLPE cables?

PVC cables are flexible, affordable, and suitable for low-voltage, indoor applications, while XLPE cables offer superior durability, higher temperature tolerance, and better chemical resistance, making them ideal for high-voltage and industrial uses.

- Which type of cable type is more commonly used: PVC or XLPE?

PVC cables are more commonly used for residential and low-voltage applications due to their affordability and flexibility, while XLPE cables are preferred for industrial applications requiring higher performance and durability.

- How to determine which cable type is good for a specific application?

To determine the appropriate cable type, consider factors such as the operating environment (indoor or outdoor), electrical load (low or high voltage), temperature tolerance, chemical exposure, and budget constraints.

Sources:

- https://tratosgroup.com/products/cables-by-type/pvc-cables/

- https://www.performancewire.com/xlpe-cable-and-frequently-asked-questions-faq/#:~:text=What%20Is%20XLPE%20Cable%3F,heat%2C%20moisture%2C%20and%20chemicals.

- https://uk.prysmian.com/media/news/pvc-vs-xlpe

- https://www.performancewire.com/xlpe-cable-and-frequently-asked-questions-faq/

- https://instrumentationtools.com/difference-between-pvc-xlpe-and-insulated-cables/