Soldering vs. Crimping in Lugs: Choosing the Right Termination Method For Cable Lugs

When it comes to making solid electrical connections, choosing the right termination method for cable lugs is critical. A precisely executed termination not only guarantees the effectiveness, safety, and durability of the connection but also prevents potential malfunctions and inefficiencies resulting from a subpar termination.

Cable lugs play a crucial role in linking cables to electrical devices, specifically for securing a steadfast and enduring connection. The two primary techniques for affixing these lugs are soldering and crimping, each with its own distinct benefits and specific use cases.

Mahendra Fact File: Copper cable lugs were the MVP in 2020 for their unbeatable safety and efficiency, but aluminium is speeding up to overtake by 2028, driven by cost reduction and technological innovations.

Let’s get started with the basics.

What is Soldering in Cable Lugs?

Soldering is a method where a metal alloy, called solder, is melted to join the cable and lug, creating a permanent connection. This process forms a strong bond, ensuring a highly conductive connection, which makes it a go-to for precision applications where reliability is paramount.

When is Soldering Best?

Soldering excels in scenarios where electrical conductivity plays a vital role, especially in high-performance or delicate electronic devices. It is commonly utilized for:

- Battery cables in vehicles

- High-precision electronics

- Small-gauge wires

However, mastering the art of soldering requires finesse. Excessive heat can harm both the cable and lug, emphasizing the importance of achieving proper solder flow. Maintaining the right temperature and ensuring a smooth, solid connection are crucial to prevent potential issues down the line.

What is Crimping in Cable Lugs?

Crimping is a process that entails using pressure (instead of heat as in the case of soldering) to mechanically unite the lug and the cable. Crimping tools press the cable into the lug, altering both the conductor and connector to establish a secure bond. This method is often quicker than soldering as it doesn’t involve heat, making it ideal for swift installations.

When is Crimping Best?

Crimping is favoured for its speed and efficiency, particularly in large-scale projects or environments requiring rapid and repetitive connections. It’s ideal for:

- Heavy-duty industrial applications

- Large cables and wires

- Situations where time efficiency is crucial

Mastering proper crimping technique is essential to guarantee a reliable connection. By utilizing appropriate tools, such as Jainson crimping tools, and applying just the right amount of pressure, you can make all the difference between a secure crimp that lasts versus one that may falter over time.

Benefits of Soldering Cable Lugs

Benefits:

- High Conductivity: Soldered joints have minimal resistance, providing excellent electrical performance.

- Permanent Bond: Soldering creates a long-lasting, durable connection.

- Precision: Ideal for intricate connections requiring detailed work.

Techniques:

- Avoid Overheating: Excessive heat can damage the cable or lug.

- Ensure Proper Solder Flow: The solder should fill the joint, ensuring full contact between the cable and lug.

- Use High-Quality Soldering Tools: A reliable soldering iron and quality solder can make all the difference.

Benefits of Crimping Cable Lugs

Benefits:

- Speed: Crimping is fast and efficient, making it a top choice for large projects.

- Durability: Proper crimping creates a tough mechanical connection.

- No Heat Required: Crimping avoids the risks associated with overheating, making it ideal for sensitive environments.

Techniques for Proper Crimping:

- Use the Right Tools: High-quality crimping tools, such as Jainson crimping tools, ensure effective crimps.

- Apply Correct Pressure: Too much or too little pressure can compromise the connection, so follow the tool’s guidelines.

- Double-Check Your Crimp: Ensure the cable is tightly secured in the lug without gaps or movement.

Crimping vs. Soldering: A Comparative Analysis

When choosing between crimping and soldering, it’s important to consider the strengths and weaknesses of each.

| Crimping | |

| Strengths | Weakness |

| Fast and efficient, suitable for high-reliability applications | Requires specific tools, which can be costly |

| Creates a secure, airtight seal that protects against environmental factors like moisture and dust | Must be done correctly; improper crimping can lead to unreliable connections |

| Can be performed manually or automated for consistent results | Quality depends on the technician’s skill level |

| Soldering | |

| Strengths | Weakness |

| Economical, requiring minimal tools and materials | Generates heat, which can damage components if not managed properly |

| Provides a highly conductive and permanent connection | Time-consuming and can lead to unreliable joints if not executed well |

| Suitable for general-duty applications requiring reliable signal transmission | More sensitive to corrosion and vibration without proper technique |

Choosing the Right Termination Method for Cable Lugs

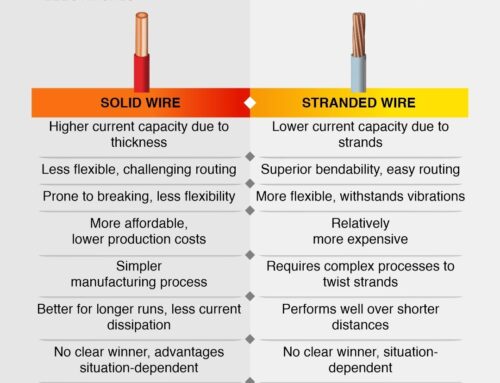

To choose between soldering and crimping, consider factors such as:

- Cable Size: Larger cables are often better suited for crimping, while smaller cables benefit from soldering.

- Application Type: Precision electronics usually favour soldering, while industrial applications tend to prefer crimping.

- Speed vs. Conductivity: Crimping is fast but soldering provides better conductivity.

Also, consider the environmental factors, such as temperature and moisture, which could affect the longevity of the connection.

Proper Installation Techniques for Cable Lugs

To ensure maximum performance and longevity, both crimping and soldering require the right technique:

Crimping:

- Use the correct lug size for the cable.

- Ensure the crimp is tight and free from gaps.

Soldering:

- Use flux to clean the cable and lug.

- Avoid cold solder joints by ensuring the metal surfaces are properly heated.

- Proper installation is key to avoiding future connection failures, so take the time to get it right.

Conclusion

When it comes to your electrical system, making the right choice on how to terminate your cable lugs is crucial for ensuring safety, reliability, and longevity. Whether you decide to go with crimping or soldering depends on various factors such as the type of cable being used, the requirements of your project, and the operating environment.

Crimping works well for creating quick and sturdy connections, particularly in tough conditions, whereas soldering provides accurate and highly conductive links suitable for applications that need signal integrity. By understanding the specific needs of your project, you can choose the termination method that will deliver optimal performance.

FAQs

- Which is better—soldering or crimping?

Both have their strengths. Soldering provides excellent conductivity and precision, while crimping is faster and more durable for larger cables.

- What are the 4 types of cable termination?

Soldering, crimping, screw-on, and compression fittings are the four main types of cable termination.

- How can I ensure a proper installation of cable lugs to avoid future issues?

Follow manufacturer guidelines, use high-quality tools, and double-check the integrity of the connection after installation.

Source Links:

- https://www.mgelectrica.com/what-are-cable-lugs/#:~:text=Cable%20lugs%20are%20devices%20used,ends%20of%20battery%20jumper%20cables.

- https://www.icrimptools.com/blogs/crimping/should-i-crimp-or-solder-battery-cable-lugs#:~:text=In%20most%20cases%2C%20soldering%20is,gauge%20cabling%20like%20battery%20cables.

- https://www.icrimptools.com/blogs/crimping/should-i-crimp-or-solder-battery-cable-lugs#:~:text=In%20most%20cases%2C%20soldering%20is,gauge%20cabling%20like%20battery%20cables.

- https://www.sig4cai.com/soldering-or-crimping-which-is-better-for-your-electrical-needs/

- https://blog.peigenesis.com/soldering-vs-crimping-advantages-disadvantages

- https://www.icrimptools.com/blogs/crimping/should-i-crimp-or-solder-battery-cable-lugs#:~:text=In%20most%20cases%2C%20soldering%20is,gauge%20cabling%20like%20battery%20cables.

- https://selterm.com/blogs/selterm/crimping-vs-soldering-choosing-the-right-method-for-battery-cable-lugs

- https://www.powerandcables.com/conductor-connectors-crimp-v-mechanical-connectors-with-joints-terminations/

- https://selterm.com/blogs/selterm/how-to-choose-the-right-cable-lugs-a-comprehensive-guide#:~:text=Cable%20Size:%20Measure%20the%20size,to%20ensure%20easy%20cable%20insertion.

- https://axis-india.com/installation-of-cable-lugs/